Nano.T® technology

How the nanotechnology in foliar applications works

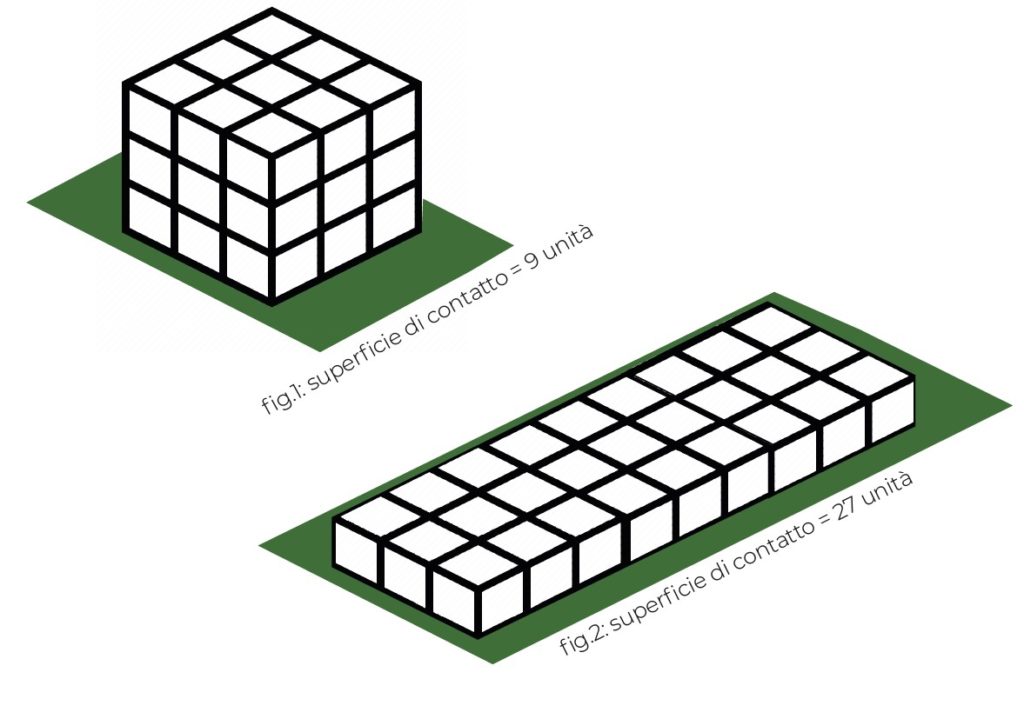

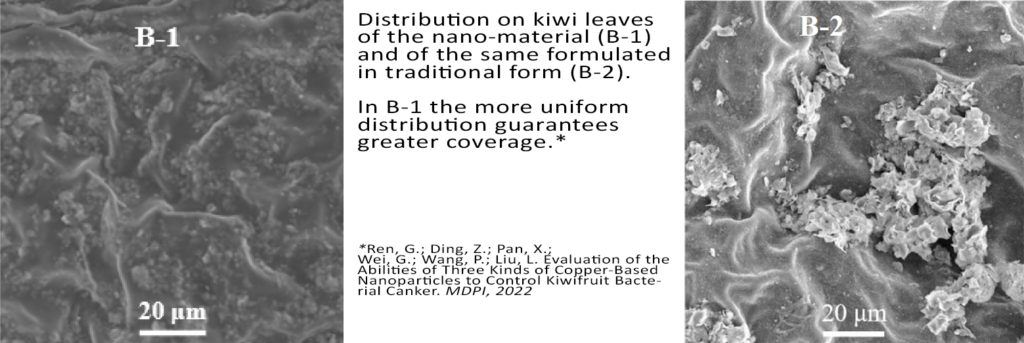

The NANO.T technology allows to have in one litre of product millions of billions of particles with a dimension ranging between 1 and 100 nanometres with a wide specific surface area determining a high effectiveness and allowing a dense coating of the leaf (fig.2) as compared to the traditional technology (fig.1), considering the same quantity applied.

The copper example

Hydroxides, micronized vs NANO.T® Cu

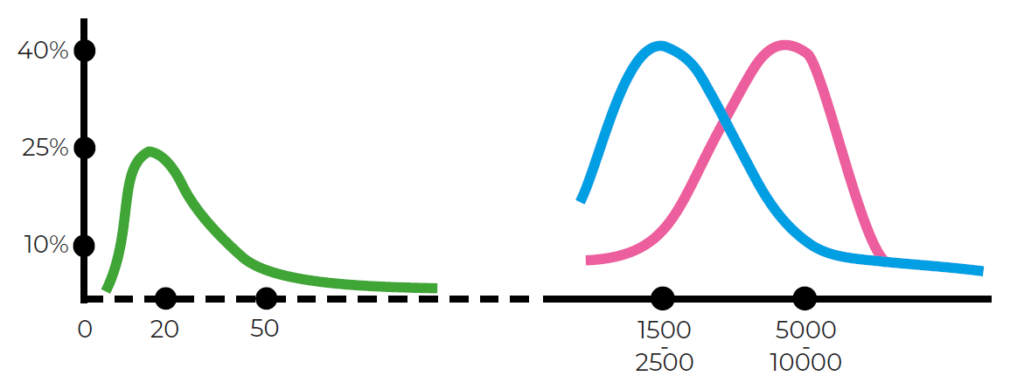

Nanoparticles have a dimension one hundred times inferior to that of other products: in the chart green curve, the majority of the particles of NANO.t Cu have a dimension of 20 nm while other standard hydroxides, pink curve, measure around 7000 nm as well as the most innovative products such as micronized, blue curve, around 2000 nm.

- They require a higher dosage due to their major dimension and inferior uniformity of distribution

- Persistence is reduced in inverse proportion to the dimension of the particles

- They can disperse in the environment accumulating in the soil

Nanotechnology in foliar applications: Nano.T®Cu

- High effectiveness at low dosages nanoparticles have a wide surface contact area and distribute uniformly on the leaf, improving absorption

- Persistent on the leaf the formulation in colloidal suspension allows a better adhesive capacity to foliar waxes

- Lower environmental impact thanks to the low dosage and the improved adhesive capacity

- It improves the effectiveness of the products combined with it (wide range of miscibility with both fertilizers and/or pesticides)

The calcium example

Chloride vs nano-calcium

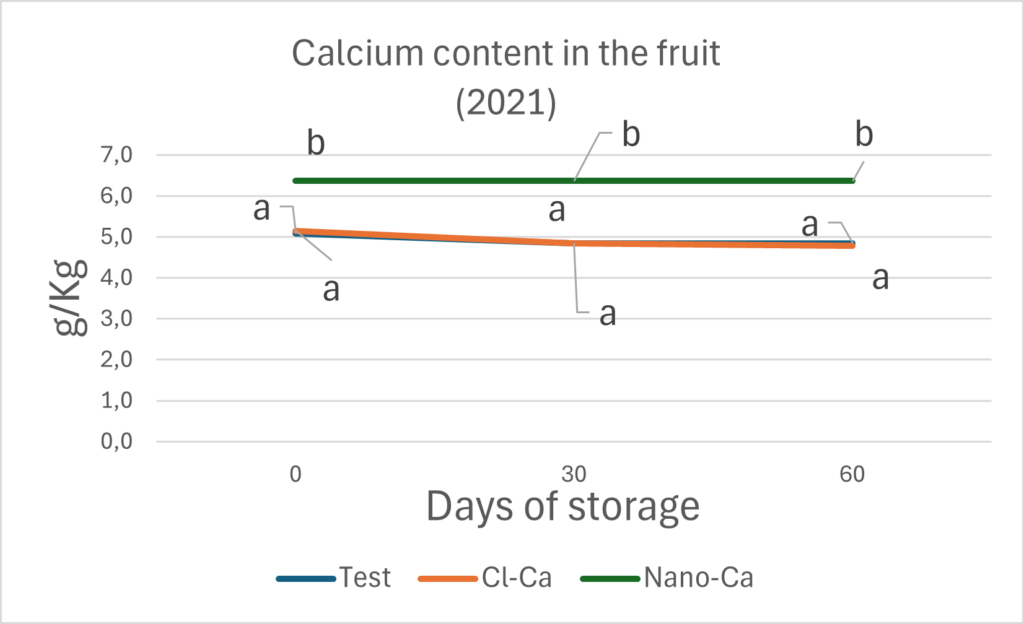

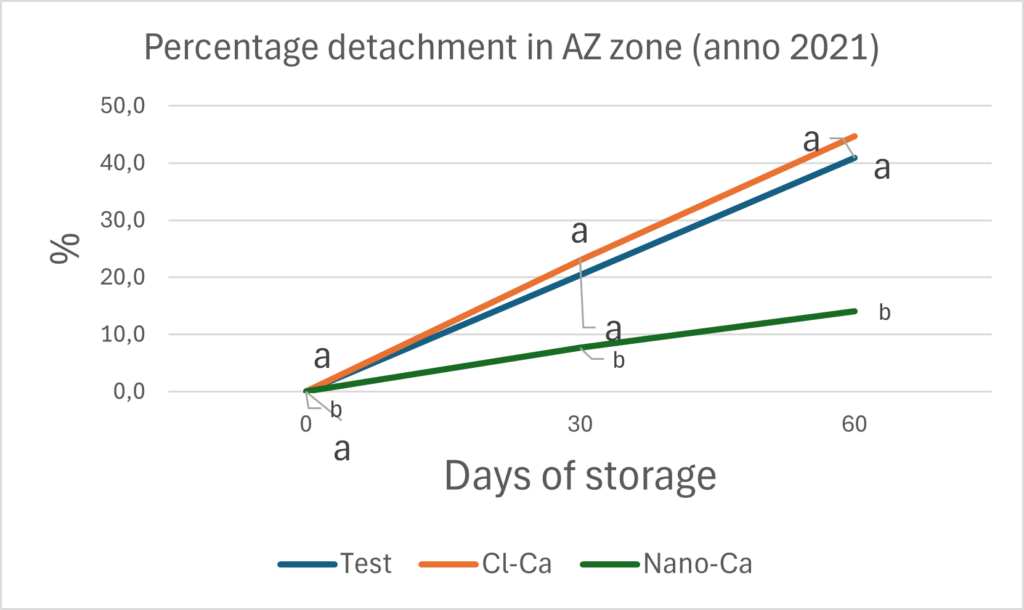

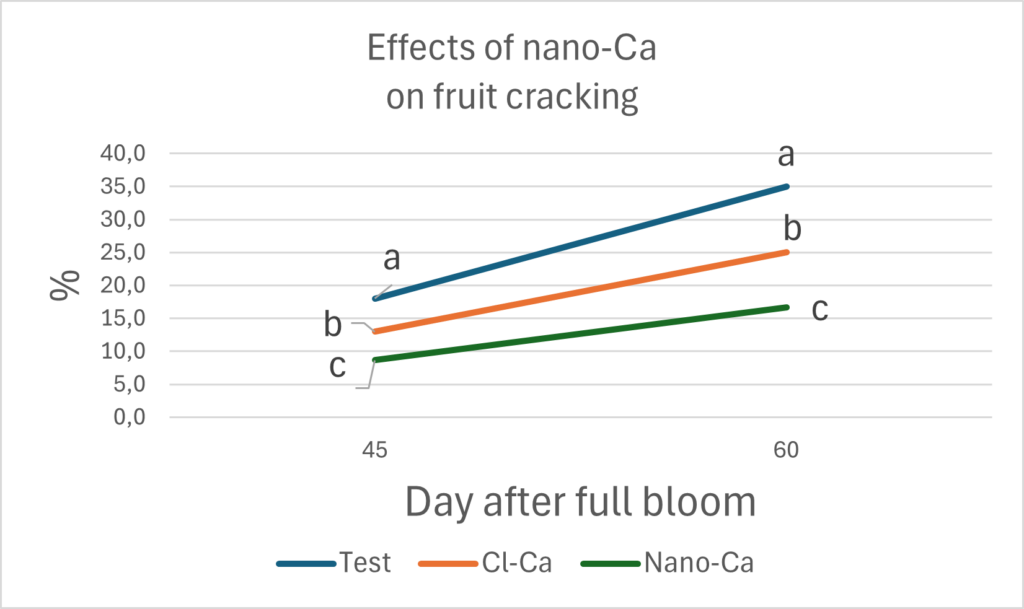

Graphs 1 and 2 tablegrape; graph 3 nectarine.

Source: Author’s adaptation from:

- Mingtao Zhu et.al. (2024). Preharvest Nano‑calcium Reduces the Table Grape Berry Abscission by Regulating Ethylene Production During Storage. Journal of Plant Growth Regulation 43:1400–1409

- Mingtao Zhu et.al. (2023) Nano-calcium alleviates the cracking of nectarine fruit and improves fruit quality. Plant Physiology and Biochemistry 196 (2023) 370–380. Grafici riadattati dall’autore.

Calcium chloride

- It is poorly mobile within the plant. It is absorbed by the roots and, through the xylem vessels, tends to settle on the leaves involved in photosynthesis, only reaching a small amount of the fruit through transpiration.

- If applied to leaves, it tends to stick to their surfaces.

- High effectiveness at low dosages nanoparticles have a wide surface contact area and distribute uniformly on the leaf, improving absorption

- Increased calcium content in the berries, rachis, and abscission zone. This is because nano-Ca, compared to traditional calcium-based fertilizers, is more easily absorbed by the plant.

- Inhibition of ethylene production induced by calcium content

- Increased calcium pectate content

- Maintained a low percentage of berry detachment

- Increased fruit hardness and shelf life after harvest

- Reduction of fruit cracking thanks to the formation of calcium pectate in the middle lamella of the peel cell walls.